In today’s industrial and construction environments, safety is paramount. One critical aspect of workplace safety is ensuring that machinery and electrical systems are properly shut down before maintenance or repairs are carried out. An energy isolating device is a fundamental tool that plays a vital role in this process. But what exactly is An Energy Isolating Device is, and why is it so important?

What is an Energy Isolating Device?

An energy isolating device is a mechanical device that prevents the transmission or release of energy to machinery, electrical systems, or hazardous systems. This type of device ensures that energy is isolated from a particular piece of equipment, rendering it safe for workers to perform maintenance, repairs, or inspections without the risk of electrical shock, mechanical failure, or other potentially dangerous events.

The term “energy” in this context can refer to different forms of energy, such as electrical, mechanical, hydraulic, or pneumatic power. Therefore, an energy isolating device can be found in various industries, ranging from manufacturing plants to construction sites, where heavy machinery and electrical systems are common.

Types of Energy Isolating Devices

There are several types of energy isolating devices, and each serves a specific purpose depending on the energy form it is designed to control. Some of the most common types include:

-

Electrical Disconnect Switches

These devices are commonly used in electrical systems to completely disconnect the power source. Electrical disconnects are used to ensure that all electrical power is turned off before working on circuits or components.

-

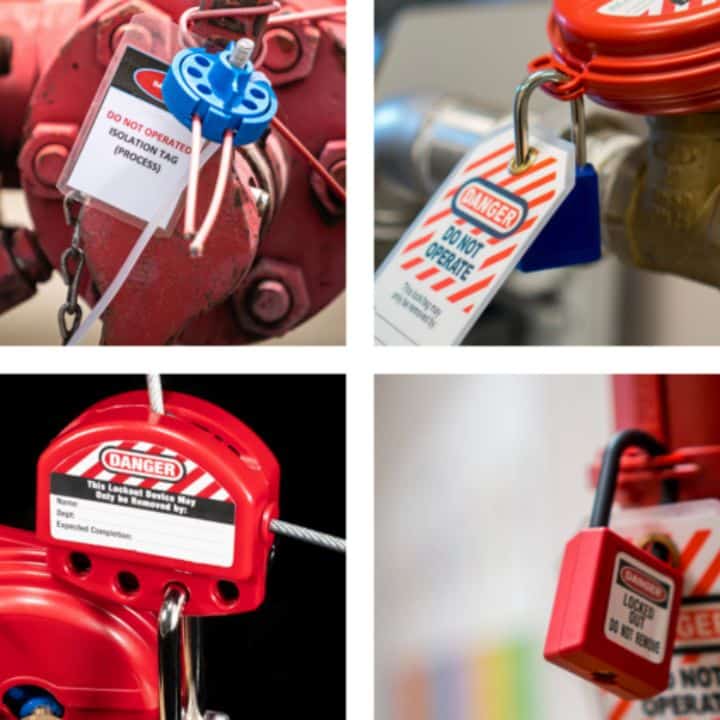

Lockout/Tagout (LOTO) Devices

A popular safety protocol, Lockout/Tagout (LOTO) devices are used in conjunction with energy isolating devices. Workers can lock the device into the off position and tag it to indicate that maintenance or repair is underway.

-

Valves

For systems that operate with hydraulic or pneumatic pressure, energy isolating valves can shut off or control the flow of fluid or gas to a system.

-

Mechanical Disconnects

For mechanical energy systems, disconnects such as clutches or brakes can be employed to isolate moving parts, preventing any accidental motion during maintenance.

Why Are Energy Isolating Devices Crucial?

Energy isolating devices are a crucial part of industrial safety and play an important role in reducing workplace accidents. The Occupational Safety and Health Administration (OSHA) and other regulatory bodies mandate the use of these devices to prevent injuries, which can be severe or even fatal, due to the release of energy during maintenance activities.

Consider the potential risks if an energy isolating device is not used properly:

- Electrical Shock:

Electrical systems can be deadly if workers are not fully protected. An energy isolating device ensures that the flow of electricity is completely cut off, eliminating the risk of electrocution. - Mechanical Failure:

Many machines, especially in manufacturing environments, contain moving parts that could cause severe injuries. An energy isolating device makes sure that these parts are fully stopped before any maintenance is done. - Hydraulic or Pneumatic Pressures:

Systems relying on pressure can cause dangerous releases of fluid or gas if not properly isolated, posing a serious risk to workers.

Read more: Haitian Creole Translator Device

Lockout/Tagout and the Role of Energy Isolating Devices

Lockout/Tagout (LOTO) is a critical safety practice that directly involves the use of energy isolating devices. The LOTO procedure requires that energy sources to equipment or machinery be turned off and secured using energy isolating devices before maintenance or repair work begins.

Under LOTO protocols, workers use specific energy isolating devices like locks, tags, and disconnects to prevent accidental energization of equipment. This practice ensures that workers are protected while working on potentially hazardous equipment, as the energy isolating device prevents any form of energy from being released.

The effectiveness of LOTO depends on the proper selection and application of energy isolating devices. Without them, workers may inadvertently re-energize systems or expose themselves to harmful conditions. For example, if an electrical disconnect is not engaged properly, there is a significant risk of electrical shock. Similarly, failure to properly isolate mechanical systems can lead to injury from moving parts.

OSHA Regulations and Energy Isolating Devices

In many jurisdictions, including the U.S., OSHA has set clear guidelines for energy control procedures, requiring employers to implement energy isolating devices as part of their lockout/tagout programs. OSHA’s standard for Lockout/Tagout (1910.147) specifically defines and addresses the need for energy isolating devices. According to the guidelines, “an energy isolating device must be capable of being locked out.”

These regulations are designed to safeguard workers from unexpected energy releases that could lead to injury. Employers must not only ensure the availability of proper energy isolating devices but also provide adequate training to workers on how to use them correctly. This helps in maintaining a safe work environment and reducing the number of workplace accidents.

Choosing the Right Energy Isolating Device

- For Electrical Systems:

A suitable electrical disconnect or circuit breaker is essential for safely isolating electrical energy. - For Hydraulic or Pneumatic Systems:

Valves or pressure-relief devices are necessary to isolate these systems from any stored energy. - For Mechanical Equipment:

Mechanical disconnects such as clutches, switches, or brakes are needed to stop the motion of moving parts.

The energy isolating device must also be durable, reliable, and easy to operate. Inadequate devices that fail to properly isolate energy can lead to hazardous situations. Therefore, regular maintenance, testing, and inspection of energy isolating devices are essential for ensuring their effectiveness.

Best Practices for Using Energy Isolating Devices

To maximize the effectiveness of energy isolating devices and ensure safety, follow these best practices:

-

Regular Inspections

Periodically inspect and test all energy isolating devices to ensure they are functioning properly. This will help prevent failures when they are needed most.

-

Proper Training

Ensure that all employees are properly trained in energy isolation procedures, including how to identify, operate, and apply the correct energy isolating devices.

-

Clear Labeling

Label energy isolating devices clearly to indicate which systems they control. This helps workers quickly identify the correct device and avoid confusion.

-

Documentation

Maintain detailed records of energy isolation procedures, inspections, and maintenance. This can help track the safety of systems and ensure compliance with regulations.

-

Use Lockout/Tagout:

Always use lockout/tagout procedures alongside energy isolating devices. This is a proven method for preventing accidental energy release during maintenance.

Conclusion

An energy isolating device is a vital tool in any workplace where machines or electrical systems are present. It plays a key role in ensuring the safety of workers by preventing the unexpected release of energy during maintenance or repair work. By using the appropriate energy isolating devices, implementing lockout/tagout procedures, and adhering to OSHA guidelines, employers can significantly reduce the risk of workplace injuries and fatalities.